TFTAK Pilot Plant

TFTAK Pilot Plant is constantly growing. We are ready to bring your idea from lab scale to pilot plant and then to production in the industrial level.

We help to scale-up in food product development

Often the idea looks delicious and manageable in a smaller production setting but scaling up a production level can be challenging. Scale-up in food product development can be made easy in our piloting plant.

No worries, our team will support you further on with technology transfer and implementation of production as well.

Our equipment: Upstream processes

Lab mixer Limitech MyMix

This fully scalable 10 L mixer (product volume ca 8 L) lab mixer / cooking kettle gives the same output as a 3000 L mixer – a successful recipe can be transferred to large scale production.

-

Fully scalable

-

10 L mixer (product volume ca 8 L) gives the same output as a 3000 L mixer – a successful recipe can be transferred to large scale production

-

Indirect heating or direct steam injection

-

The lab mixer is perfect for the following solutions: prepared foods, preserves, dairy, cheese, sauces, spreads, ice cream, desserts, health care, confectionary, etc.

Extruder Brabender KETSE 20/40

With this twin-screw extruder, we can develop new recipes or simulate processes exactly to scale!

-

Low and high moisture extrusion

-

Texturize various materials, such as for example proteins, starch, cereals and pasta

-

Six dosing options along the process area

-

Screw elements can be combined individually

-

Rotational speed of up to 1200 rpm

The extruder offers several options to work with a broad range of raw material to develop exciting final products:

-

Protein extrusion – low and high moisture extrusion

-

Meat alternatives

-

Ingredients – modified flours (e.g. pre-gelatinized flours), modified starch

-

Cereals – chocolate crispies, loop; general breakfast cereals

-

Snacks – crackers, flatbreads

-

Pasta extrusion – short and long pasta

Scraped surface heat exchanger Armfield FT25BA

Continuous ice cream machine for delicious product development.

-

Duplicates full-scale process

-

Fast, accurate new product development

-

Barrel speeds to over 1400 rpm

-

Barrel length 0.35 m, barrel working pressure 3 –10 bar

-

Throughput 20 L/h

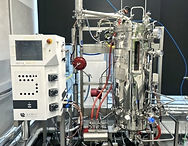

Fermentation systems and applications

TFTAK has seven Applikon 1L bioreactors and 7L and 70L system. Fermenters and isothermal microcalorimeters are indispensable to scale up the microbial cell culture development.

-

The bioreactors are equipped with off-gas analysis and turbidity probes and ready for continuous, fed-batch and batch fermentation at controlled pH, temperature and gas environment.

-

We have excellence in cultivation of both aerobes and strict anaerobes.

Cultivation equipment

Strict anaerobes demand oxygen free environment.

-

TFTAK has Coy type B anaerobic chamber that makes it possible to handle species that do not tolerate oxygen.

Isothermal microcalorimetry

A perfect tool for growth medium screening and other applications.

-

Isothermal microcalorimeter determines heat produced during microbial growth with high precision.

-

The main strength of the device is the fact that it could be used in opaque environments that optical density based devices cannot handle.

-

This is our main tool for medium screening experiments.

Air Classifier mill Hosokawa

-

Pretreatment with hammer mill

-

Classifier wheel 200um-10um

-

Produced material particle distribution report

Hammer Mill

-

Pretreatment with hammer mill

-

Classifier wheel 200um-10um

-

Produced material particle distribution report

Steam Oven

-

Cooking simulations

-

Steam option

Our equipment: Downstream processes

Decanter Lemitec MD60

-

Decanter throughput 1 - 30 L/h

-

Inlet tube diameter 8 mm

-

Maximum acceleration 3300 g

-

Maximum speed 10 000 rpm

-

Differential speed 1 - 200 rpm

Filtration system MMS

-

Filter library – exchangeable filters

-

Micro-, ultra-, and nanofiltration, reverse osmosis

-

Concentration of liquids, removal of specific compounds (e.g. minerals or lactose), etc.

-

Thickening

-

Fully scalable

Pasteurizer Armfield FT74XTS

HTST / UHT system is optimized for product-development use. That makes the process easily scalable to production.

-

High temperature short time

-

Temperatures up to 150 ºC

-

Time 2 s –2 min

-

Plate-type and tubular-type heat exchangers

-

Throughputs up to 10 L/h (plate heat exchanger)

-

Optimized for product-development use –easily scalable to production

-

Pasteurizer Armfield FT74XTS

Spray dryer GEA Niro Mobile Minor

Pilot scale spray dryer for production of milk powder and other powders.

-

Minimum volume 3 L

-

Fountain nozzle

-

Approx. 100-300 g powder / hour

-

Drying conditions 70-250 °C

Lyophilizer

-

15-litre condenser capacity

-

Temperature -100°C

-

Condenser ice capacity of 4kg/24 hours - max 7 kg in total

Autoclave Systec DC 150

-

Programmable autoclave

-

Temperature sensor

-

Up to 134°C

Modified atmosphere bottle filler

-

CO2

-

N2

-

60% CO2 / 40% N2

Packaging options

-

Modified atmosphere

-

Vacuum

-

Trah

Aseptic Packaging Line Asepto-Fill

-

Modified atmosphere

-

Filling options: Caps with aluminum foil, bottles

Pilot production experiments with extruder Brabender KETSE

Low moisture extruded pea & oat protein

-

Highly fibrous dry material suitable for a variety of applications

-

Other sources can also be used: soy protein, wheat gluten, fava bean protein, etc

-

Can be used as a minced meat alternative in burgers, meatballs, sauces, fillings, sausages, etc

-

Long shelf life

-

Requires rehydration in water of other liquid

High moisture extruded pea & oat protein

-

High moisture meat alternatives

-

Highly fibrous material

-

Other sources can also be used: soy protein, wheat gluten, fava bean protein, etc

-

Can be used as “jerky”, in snacks, burgers, etc

-

Shorter shelf life compared to dry-extruded proteins, but does not require rehydration

-

Nutritional value and texture can be further improved by adding food fiber

Plant-based burger with improved nutritional value

-

Added food fiber

-

High quality plant-based fats

-

Flavor and aroma compounds that resemble meat

-

Emphasis on appearance looks and fries like a beef burger